Academic courses

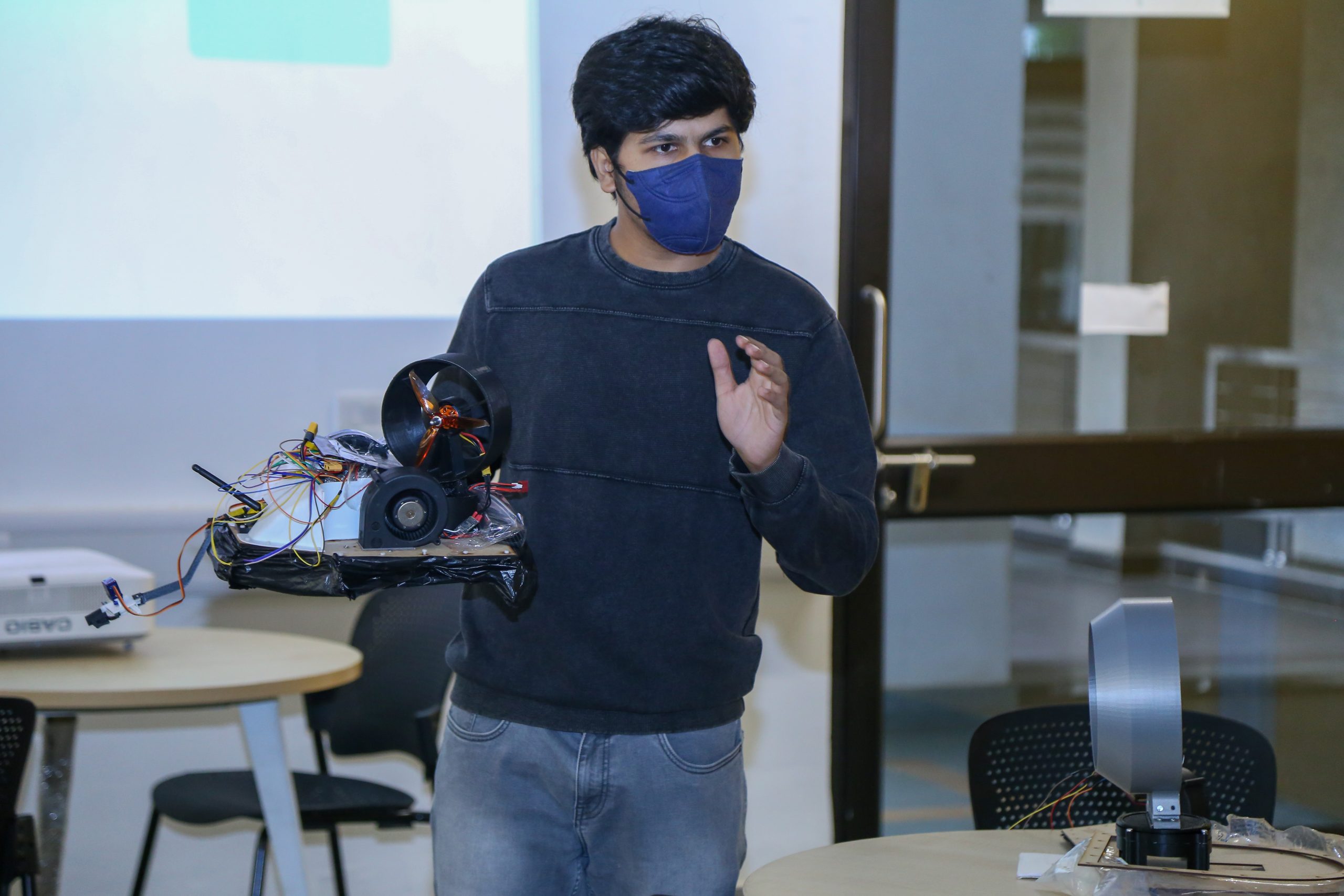

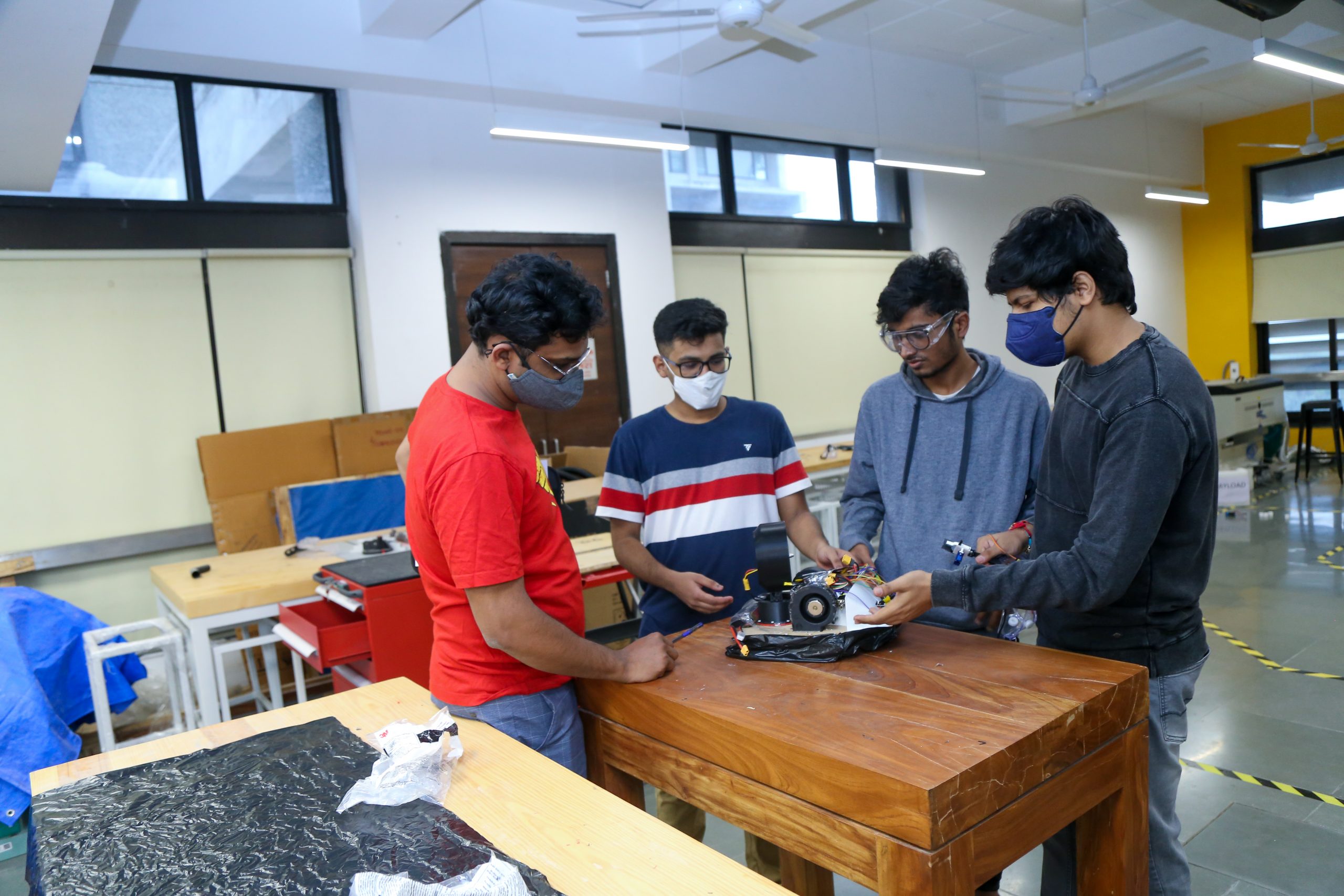

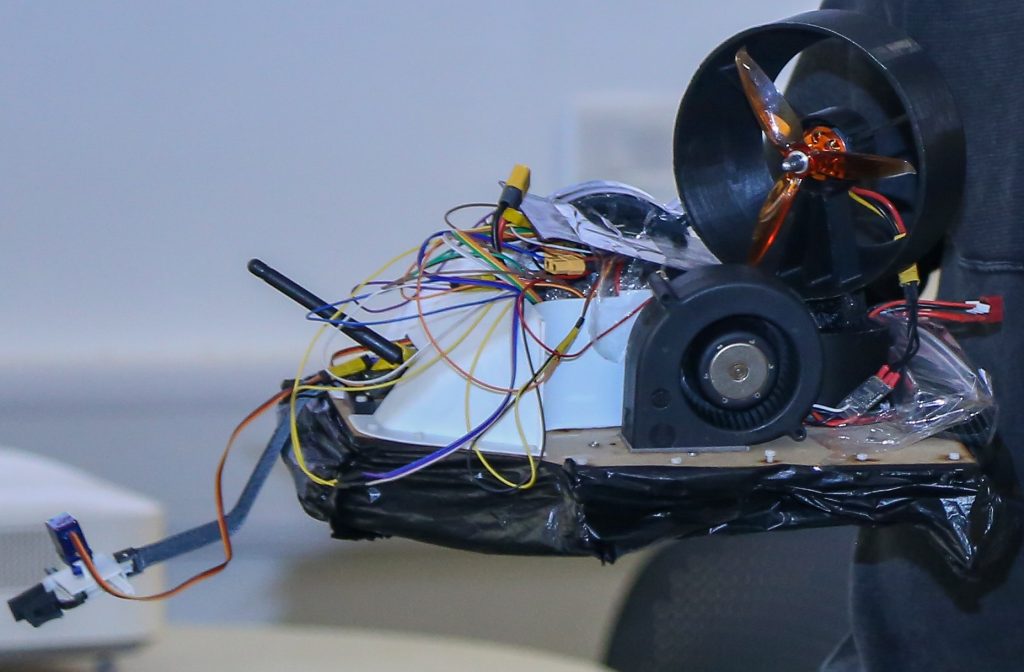

Course Output: Hovercraft Resupply Vehicle Building

Project Course Fall 2021:

Hovercraft Vehicle Building Course

Maker Bhavan Project Course

Schedule: Fall 2021 | 14 Weeks | Full semester | 4 Credits

● Prerequisite: Open to All [Interest for making, digital fabrication and creativity]

● Interdisciplinary project

● Facilitators: Tanvir Khorajiya, Aniruddh Mali

COURSE DESCRIPTION:

In a situation of natural disasters and calamities, thousands of people strive for a supply of food,

water, or power. This course will tasks students to design and make unmanned emergency

resupply Hovercraft through an iterative design process that can traverse many mediums to

deliver lifesaving aid to those in need.

OBJECTIVE

The objective will be to design and make a hovercraft at Maker Bhavan using its resources such

as 3d printing, laser cutting, electronics prototyping, power tools etc. Hovercraft should be able

to traverse the physical obstacle ground course, and also be able to pick up, carry and deliver

the payload in a defined time.

Project Course Spring 2022

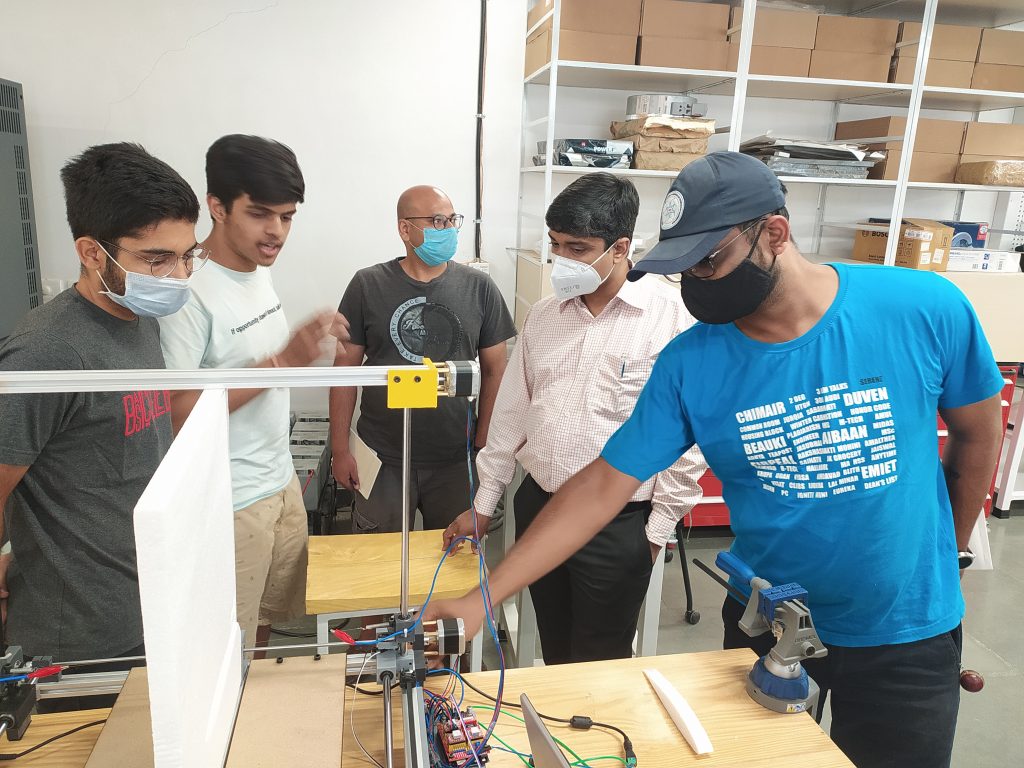

Arduino Based CNC Foam Cutter

Maker Bhavan Project Course

Schedule: Spring 2021 | 14 Weeks | Full semester | 4 Credits

● Prerequisite: Open to All [Interest for making, digital fabrication and creativity]

● Interdisciplinary project

● Facilitators: Tanvir Khorajiya, Aniruddh Mali

COURSE DESCRIPTION:

The CNC based Foam cutter is one of the fastest 3d prototyping techniques to create 3d geometrical shapes for the new product. The CNC router is used for cutting wood, acrylic and plastic material in 2D/3D shape, However, there is a unique application of CNC Foam cutter, which can cut foam sheets in 2D/3D shapes. Currently, in the market available CNC foam

cutters are of a high cost and bulky in size. This course has given a challenging task to students to design and develop benchtop/desktop size CNC foam cutters using Arduino boards.

OBJECTIVE

The objective of the Project Course was to design and develop Arduino based CNC Foam Cutter at Maker Bhavan using its resources such as Electronics Prototyping, Power Tools, 3D Printing, Laser Cutting, etc. It should be able to cut the foam sheets using a hot wire, or a special type of resistance wire which gets really hot when current flows through it. The machine should be operated by GCODE, which could be generated from 2D or 3D design. The hot wire melts or vaporizes the foam when passing through it and so the user can precisely and easily get any shape he/she want.

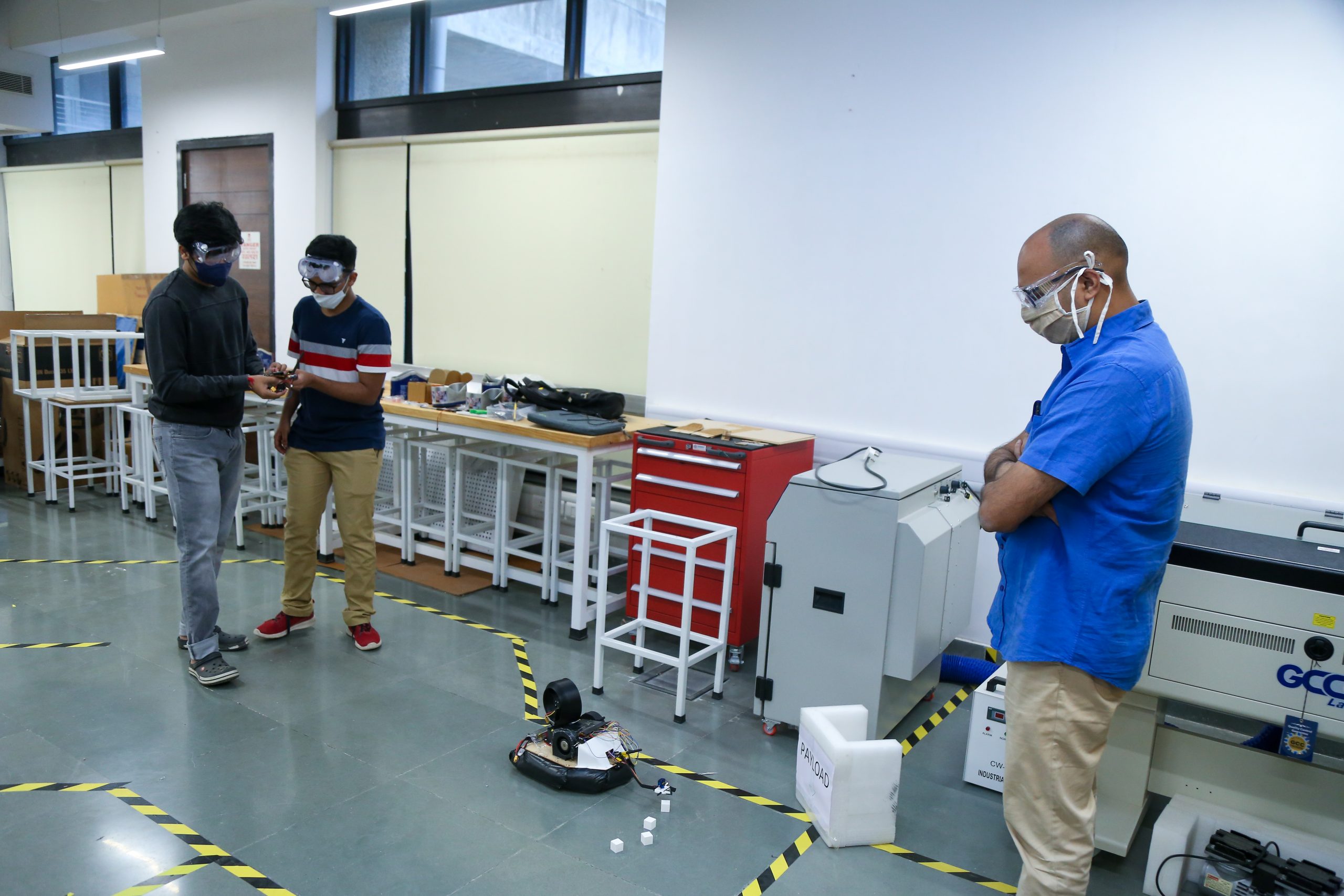

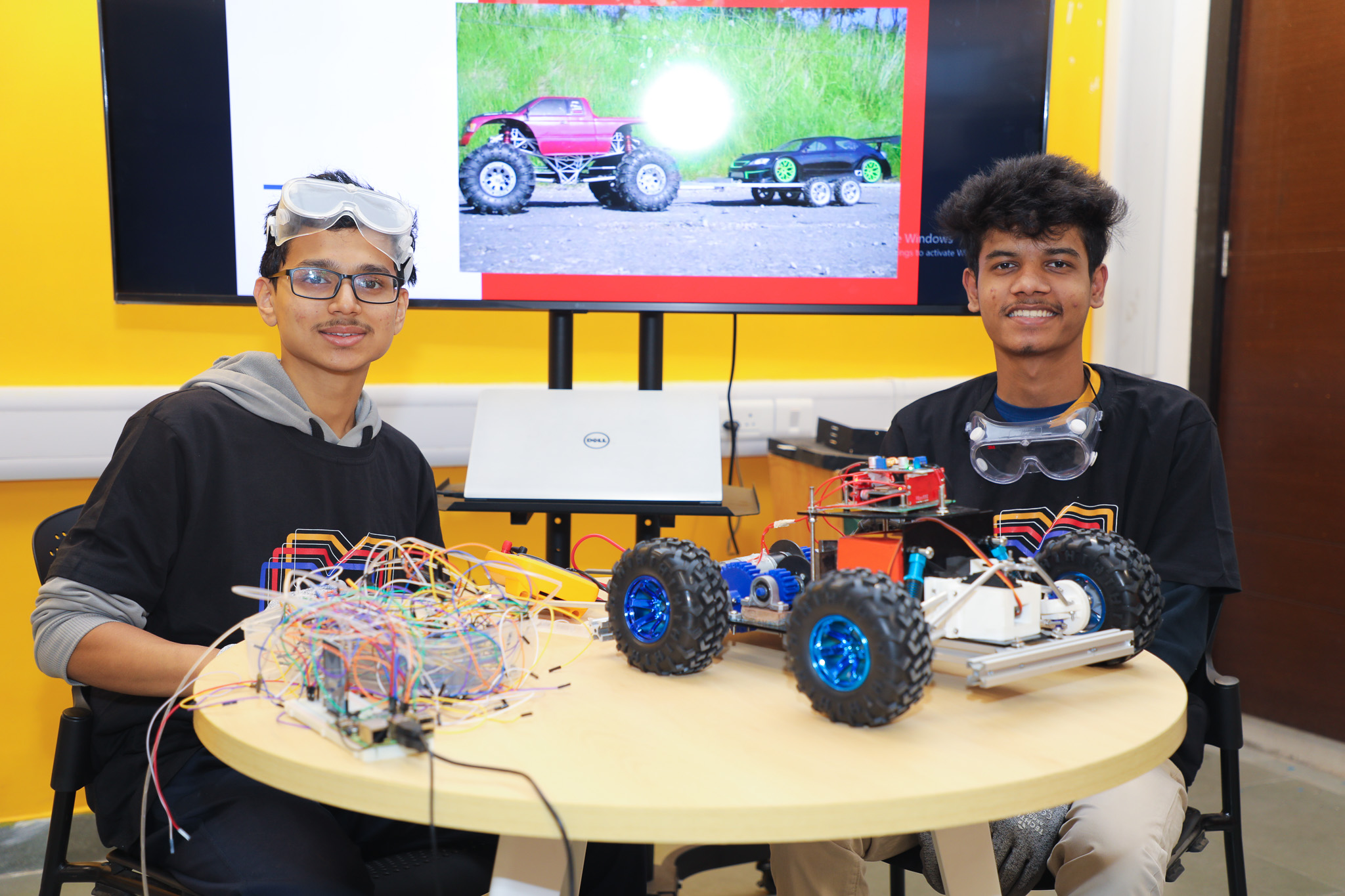

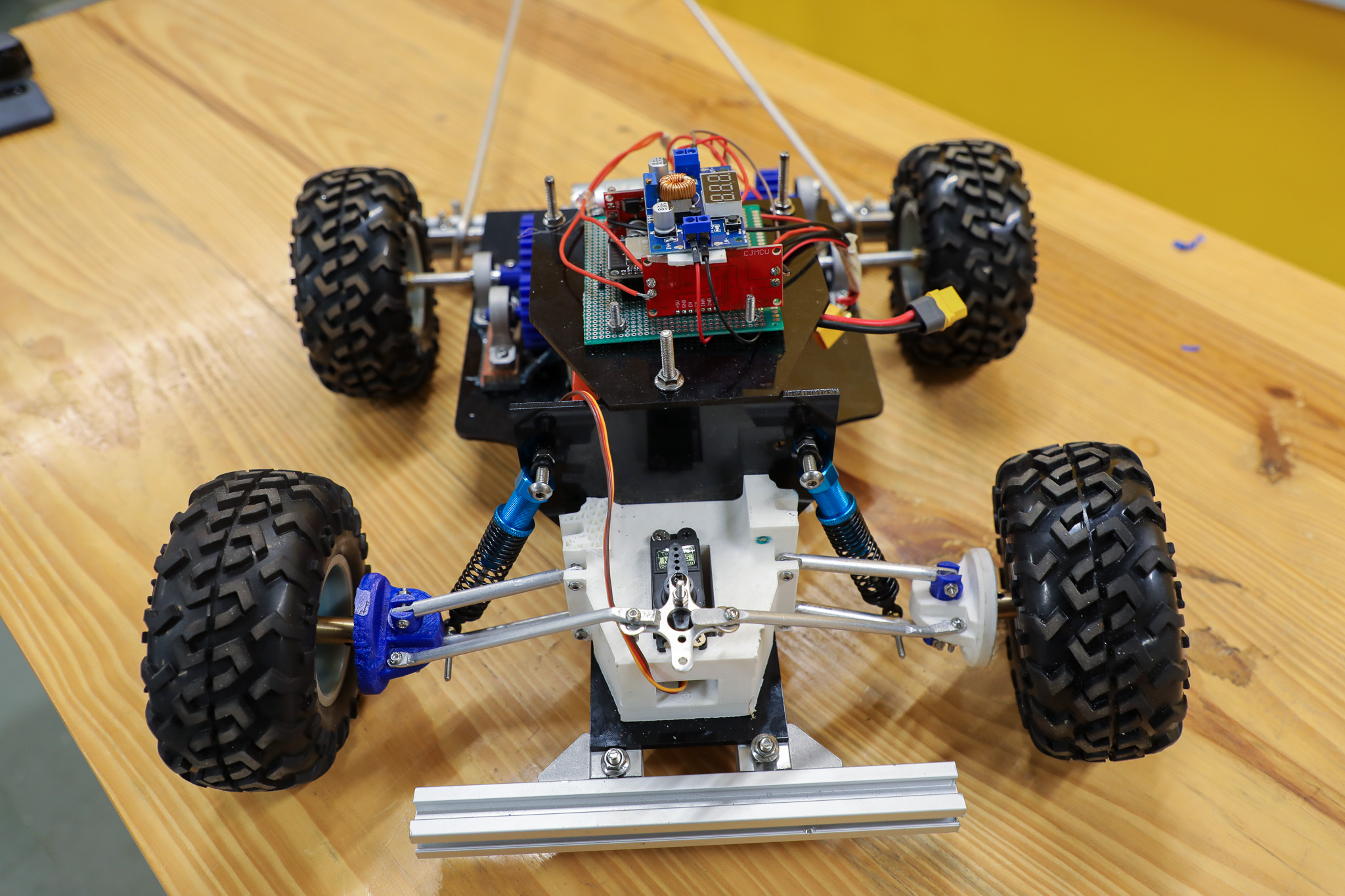

Project Course Fall 2022

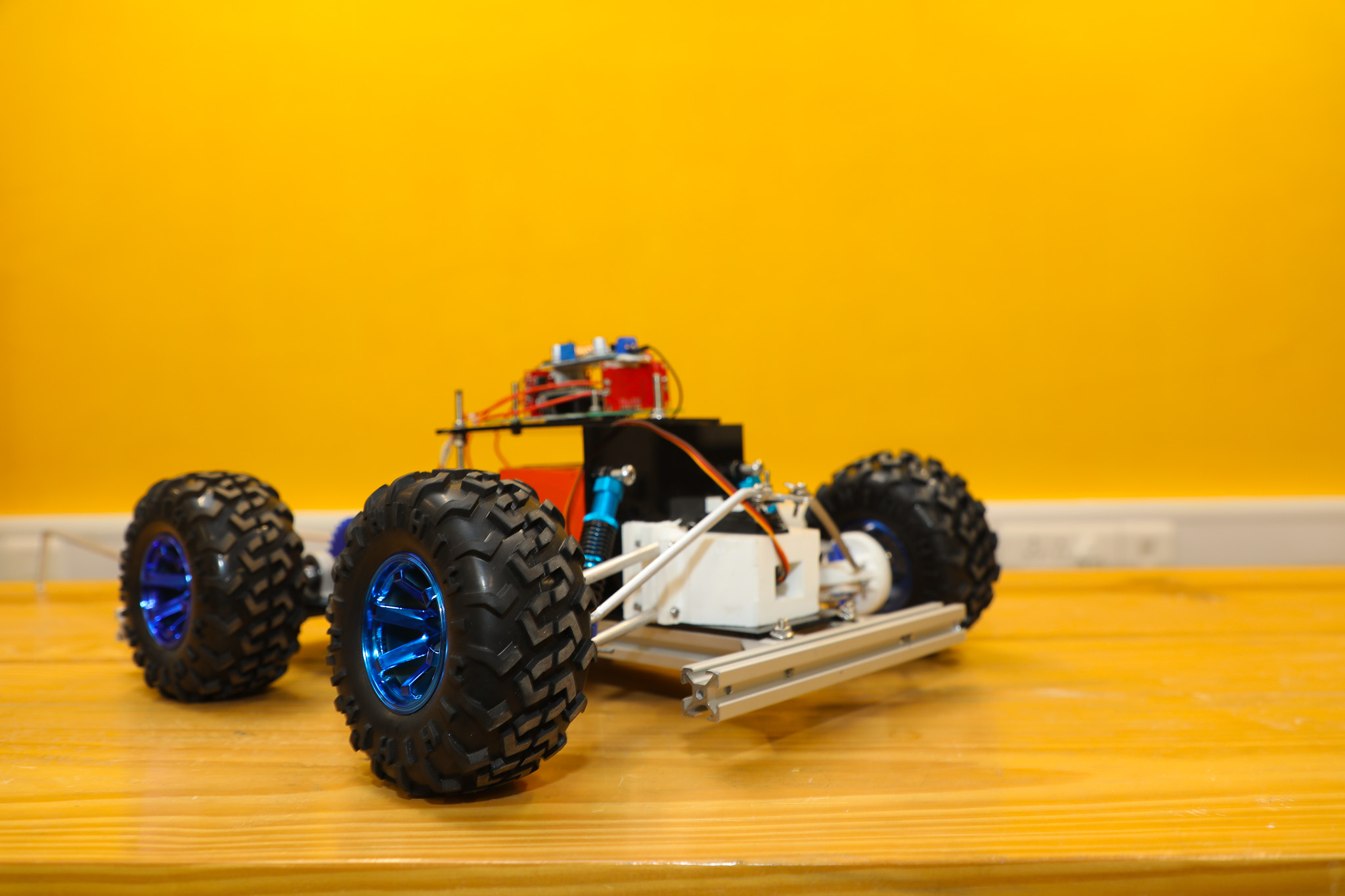

Payload Towing Remote Controlled Vehicle

Maker Bhavan Project Course

Schedule: Fall 2022 | 14 Weeks | Full semester | 4 Credits

● Prerequisite: Open to All [Interest for making, digital fabrication and creativity]

● Interdisciplinary project

● Facilitators: Tanvir Khorajiya, Aniruddh Mali

COURSE DESCRIPTION:

During this course, students has been challenged to design and make PTRCV (Payload Towing Remote Controlled Vehicle- a remote-controlled vehicle that can tow heavy-duty payload. The vehicle size constraint was not to exceed the size of 1.5 x 1.5 x 1.5 feet. The payload weight could be 15kg or more, the vehicle should be able to tow the payload from one location

to another. Students were tasked to go through an iterative design process of vehicle design which has a towing capacity of different kinds of payload, with different weights and volumes.

The potential application of such vehicles can be in warehouses of supply-chain and delivery corporations, and payload movement during natural calamities. The goal of the project was to make this vehicle from scratch, including design, prototyping and final fabrication.

OBJECTIVE

The goal of the project is to make this vehicle from scratch, including design, prototyping and final fabrication. It is envisaged that in doing this entirely hands-on project, students will acquire skills related to CAD, 3d printing, laser cutting, electronics prototyping, use of power tools, etc. The project course challenge was also open to building Robot Swarm (Collectively lesser in size than 1.5×1.5×1.5 feet) which are be able to displace or tug or tow the payload weighing 15kg or more.

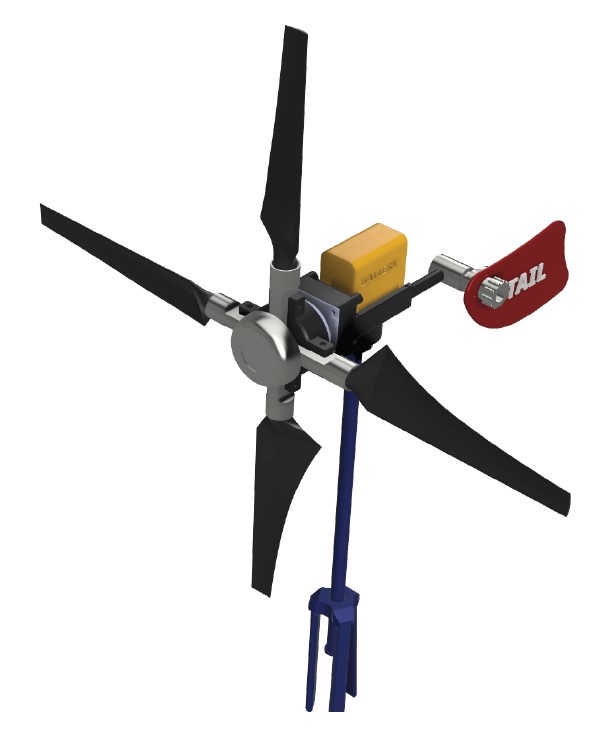

Project Course Spring 2023

Portable Windmill Design

Maker Bhavan Project Course

Schedule: Spring 2023 | 14 Weeks | Full semester | 4 Credits

● Prerequisite: Open to All [Interest for making, digital fabrication and creativity]

● Interdisciplinary project

● Facilitators: Tanvir Khorajiya, Aniruddh Mali

COURSE DESCRIPTION:

During this course, students designed and made a portable wind mill that can atleast produce

power of 12V DC, upto 100 Watt. The wind mill potentially can charge the laptop and mobile

phones. The wind mill is portable, so that it can be packed, moved together, and can be

operated at desired location. The wind mill system size limit constraint was not to exceed 3 x 2 x 2 feet, when

under packed condition. The size can be larger when it has been unpacked and under operation. Students has gone through an iterative design process of wind mill system design.

The potential application of such a system can be in school/college/office campuses, gardens and public

places or at remote locations during traveling.

OBJECTIVE

The goal of the project was to make the system from scratch, including design, prototyping and

final fabrication. It was envisaged that in doing this entirely hands-on project, students would acquire

skills related to CAD, 3d printing, laser cutting, electronics prototyping, use of power tools, etc.